|

|

||||||||||

|

|||||||||||

|

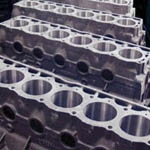

Manufacturing of Blocks At First Mate Marine, our methods are anything but routine. First, we bore every cylinder to within .004 of the finished size. Next, we use a diamond hone to ensure bore geometry is held within 300 millionths of an inch. Every block is then subjected to a surface finish test to measure the roughness and plateau finish of the cylinder wall. (With today's lightweight motor oils and low-tension oil rings, this is critical for achieving the proper ring seal.) Blocks are checked and align honed through the main bearing saddles to align and size to the proper factory specification. This is critical to maintain uniform oil clearances and good oil pressure. After all machine work is done to the block, it is cleaned completely grit free. We scrub each cylinder with soap and water and clean all oil galleys with high pressure wash.

Assembly Parts which are not cleaned, inspected and

reclaimed, are replaced with new. Because some parts,

like rockers and pushrods are subject to considerable wear, some

manufacturers don't even ship them with their finished engine. Manufacturing of Rods Manufacturing of Heads Valve seats are cut on the latest state of the art equipment, forming all three angles at once. This insures the correct seat width and concentricity for good valve seal and heat transfer. Once the head is machined, it is ready to be

assembled to factory tolerance by using all new high temperature

valve stem seals, valve springs, and hardened valve locks. Each

valve/spring combination is individually tested to provide the

correct spring pressure and vacuum tested to endure a tight valve

seal. Manufacturing of Crank/Cam

Shafts Cam lobes are reground to the same specifications as the original cam. Cams are Parker Lubrited. Camshaft Crankshaft

|